Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

Thermal spray coatings are

used in over 50 industries

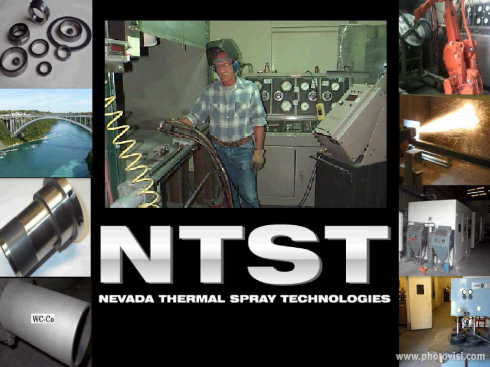

About NTST: Our Philosophy: Better, Faster, Safer, Fair Pricing

NTST specializes in high-tech thermal spray coatings technology. Non-combustible coating materials include all types and combinations of ceramics, carbides, metals, composites, and plastics that can virtually be sprayed on any substrate (e.g. metal, concrete, plastic, wood, salt, clay, rock, cardboard).

NTST conducts production spraying and thermal spray R&D for government, industry, and private concerns. The company and its personnel have played a leading role in research and development in materials and the thermal spray processes for the last 20 years, and have been continuously active in the thermal spray field since 1994.

NTST is a technology transfer spinoff company of the Idaho National Laboratory (INL) and maintains close ties to the laboratory. NTST was formed in January 2008. The company is the outgrowth of Idaho Thermal Spray Technologies that was formed in 1995. NTST has sprayed over 60 materials in detailed thermal spray R&D. Results of this research is presented in 99 papers in the open literature.

NTST Thermal Spray Capabilities

NTST only utilizes the non-combustible plasma and electric arc processes, which are similar to welding technologies, to produce coatings. A technical basis is utilized at NTST to optimize these two processes in order to produce improved coatings. This methodology can lead to modifications to equipment, coating process parameters, and material processing techniques.. Coating materials utilized in the processes include all types and combinations of ceramics, carbides, and metals. None of the coating materials used in the NTST processes are combustible.

NTST Thermal Spray Services

NTST services involve high and low production, materials engineering (e.g. parametric testing), coatings R&D, applications development, materials characterization and evaluation, process evaluation, technical consultation regarding product utilization, computational studies, and coating characterization and performance evaluation.

NTST services solve problems for the customer including product and application mismatches and product optimization. These services are unique in that most businesses don't spend the time to guarantee product quality, more often letting the customer determine the specification of the product. Thus, process evaluation is the basis of the work scope that can involve parametric testing, coating characterization, computational studies, and performance evaluation.

Due to the complexity of the thermal spray processes, services are also offered in the fields of gas dynamics, coatings, materials, heat transfer, fluid flow, thermal-hydraulics, nuclear technology, and thermochemistry. NTST maintains a database of computer programs (i.e. statistics, plasma physics, particle dynamics, coating dynamics, chemistry) for use in design and analysis.

Arc spraying of zinc coatings for a anti-corrosion application

Thermal spray applications: industrial machinery, oil and gas