Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

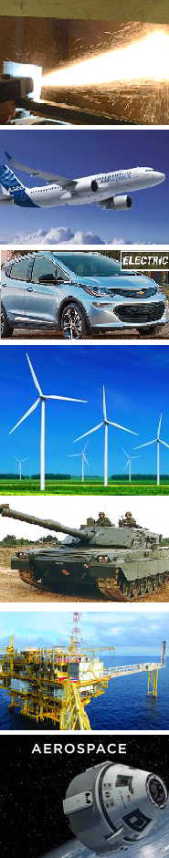

Thermal spray coatings are

used in over 50 industries

NTST Facility

NTST is presently pursuing development of the plasma, flame, HVOF, and twin-wire electric arc thermal spray processes and routinely fabricates coatings for applications for wear resistance , corrosion resistance, thermal barriers, refractories, and dimensional restoration.

The company is located in Las Vegas, Nevada. The NTST facility is currently equipped with several combustion spray systems, two 80 kW plasma spray systems, three twin-wire electric arc machines, two six-axis ABB robots, two x-y robots, various manipulators, three grit blasters, a 50 hp compressor, several spray booths, and various spray guns and supplemental peripheral equipment (i.e. grinding, lapping, etc.). These spray systems are currently operational and producing coatings.

All NTST facilities are in compliance with existing environmental laws and regulations of federal, state of Nevada, and local governments for airborne emissions, waterborne effluent, external radiation levels, outdoor noise, solid and bulk waste disposal practices, and handling and storage of toxic and hazardous materials. The thermal spray processes are non-polluting technologies with the only effluent being hot water and inert gases.