Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

Thermal spray coatings are

used in over 50 industries

Analytical Modeling

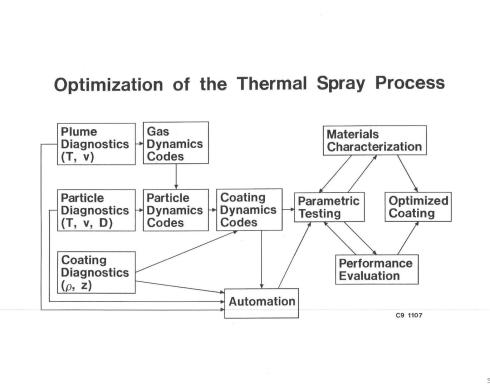

To enhance usage of the thermal spray processes, a better physical understanding of the processes is required, which involves a synergistic mix of analytical and experimental studies to optimize the thermal spray process as shown below in Figure 1.

Better understanding of coating formation can lead to the development of optimum thermal spray coatings for future industrial applications. Due to the complexity of the thermal spray processes, NTST computational services are offered in the fields of gas dynamics, particle dynamics, coating formation, materials technology, heat transfer, fluid flow, thermal-hydraulics, and thermochemistry.

NTST maintains a database of computer programs for statistics, plasma physics, particle dynamics, coating dynamics, and chemistry for use in design and analysis.

Figure 1. Optimization of the Thermal Spray Processes

Gas Dynamics

Modeling

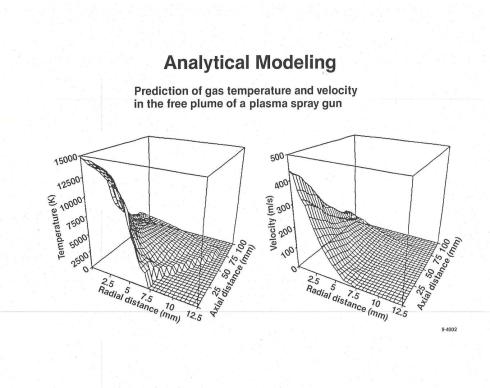

The mass, momentum, and energy conservation equations are solved assuming a two dimensional, axisymmetric model for the

thermal spray gun. The input to the code involves transport and thermodynamic gas properties, the spray gun geometry, and the system operation parameters. Typical output (e.g. Figure 2) from this

model includes temperature, enthalpy, velocity, and viscosity profiles as a function of radial and axial position in the column and plume regions of a spray gun.

Figure 2. Analytical prediction of gas temperature and velocity

Particle Dynamics

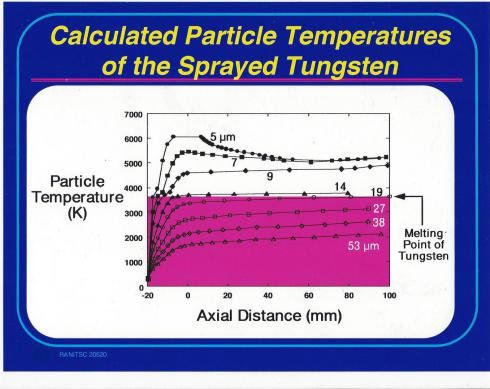

The particle dynamics code uses the temperature and velocity fields generated by the gas dynamics code to calculate the dynamics of particles injected into the plume. The primary result of the code is a description of the injected particle vaporization rate, average temperature and velocity as a function of position in the gas plume. The code calculates the histories of the injected particles one at a time, and accumulates the results for as many particles as stipulated.

For each particle injected, the specfied initial conditions are the injection location, the velocity, and the diameter. Also specified are the particle material properties. Typical output from this model includes particle temperature, velocity, and state as a function of position in the plume.

Figure 3 illustrates the calculated tungsten particle temperature as a function of location in the plume.

Figure 3. Analytical prediction of particle temperature

Coating Dynamics

Using the particle dynamics calculations, a particle plume distribution is established to study coating morphology as a function of the various process parameters. Attributes such as thickness,

hardness, porosity, deposition efficiency, tensile strength, and oxide content can be calculated.