Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

Thermal spray coatings are

used in over 50 industries

Statistical Design of Experiment (SDE)

A multitude of process parameters control the quality of thermal spray coatings. Statistically designed experimentation (e.g. Box, Taguchi SDE methods) is an efficient means of determining process factor effects on measured attributes. As coating quality requirements increase, process variations become more restrictive, and a better knowledge of the basic scientific phenomena is necessary for improved process control. Use of the SDE methodology allows unambiguous results to be obtained at a minimum cost resulting in the best possible coating.

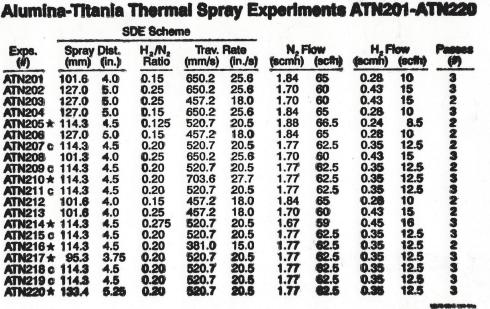

Experiments are first conducted using a specific statistical designs (e.g. factorial, fractional-factorial, central composite). The statistical analysis is accomplished with the use of software such as Design-Ease, Design-Expert, Minitab, and Taguchi. As shown in Figure 1, operating parameters are varied around typical spray parameters using the systematic SDE in order to display the range of processing conditions and their effect on the coating properties.

Figure 1. Statistically designed coating experiment

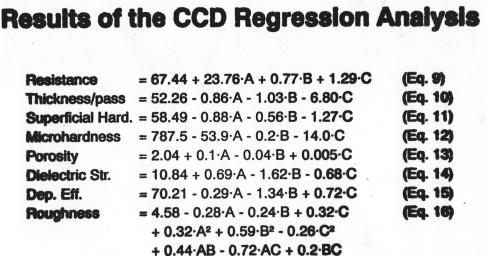

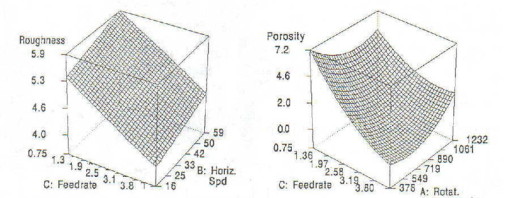

Multiple polynomical regression analysis is then used to establish the sequential relationship between the process parameters (e.g. spray distance (A), gas ratio (B), and (C) robot traverse rate), the coating properties (i.e. roughness, hardness, porosity, deposition efficiency, phase content, and microstructure) and the coating mechanical properties (e.g. tensile strength, hardness). This method yields equations (e.g. Figure 2) which allows construction of perturbation and response surface plots (e.g. Figure 3).

Figure 2. CCD regression analysis equations

Figure 3. Response surface plots for roughness and porosity