Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

Thermal spray coatings are

used in over 50 industries

Fire Prevention (FP) Coatings

NTST has developed ceramic based non-intumescent coating systems to mitigate the hazard of fire for any underlying material.

Successful thermal experimentation (i.e. continuous 15-20 minute tests at 1710F) on the FP coatings involved using a combustion torch with the flame perpendicular to the substrate hot spot. This is illustrated in Figure 1.

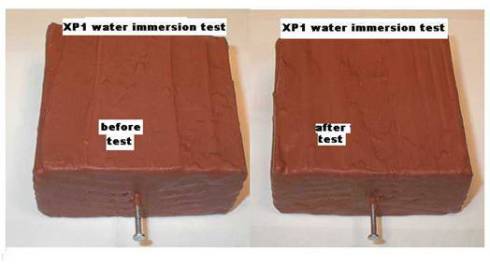

The NTST FP coating systems meet durability standards for moisture exposure (e.g. see Figure 2); and, can be applied to any material (e.g. wood, oriented strand board, or metal (i.e. Figure 3)).

The FP coating systems are more economically priced than any other fire prevention coating system in the current market. The FP coatings are friendly to the environment, and have the potential of being marketed as a green fire protective coating solutions. The coating materials are inert, non-toxic, odorless, and can be washed down the sink.

Figure 1. Thermal testing of an FP coating

Figure 2. Water immersion testing of an FP coating

Figure 3. FP coating applied to steel substrate