Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

Thermal spray coatings are

used in over 50 industries

Boron Nitride (BN) Coatings

NTST has developed the capability to fabricate hexagonal boron nitride (h-BN) coatings using the air plasma spray (APS) process. BN is extremely difficult to fabricate as a coating due to its tendency to sublime at high temperature. The hexagonal form is the most stable and softest among BN polymorphs, and is commonly used as a lubricant in many applications.

The benefits of h-BN include low density, high thermal conductivity, high temperature stability and strength, low coefficients of thermal expansion and friction, corrosion and oxidation resistance, and excellent thermal shock resistance. BN is an excellent electrical insulator at high and low temperature possessing a low dielectric constant. h-BN is soft, non toxic, and lubricious (low coeff friction = 0.15).

Major industries use h-BN including the aircraft, aerospace, chemical, electronics, glass, military, medical, metals processing, packaging, paper, power, printing, steel, and transportation industries. BN is currently used in applications to dissipate heat, and maintain electrical isolation. It finds applications in vacuum furnaces, welding equipment, and molten metal liners. The aircraft industry and the military use BN for radar components and coatings for radomes, microwave windows and antenna parts, high frequency satellites, windows in aerospace re-entry vehicles, and clearance control applications.

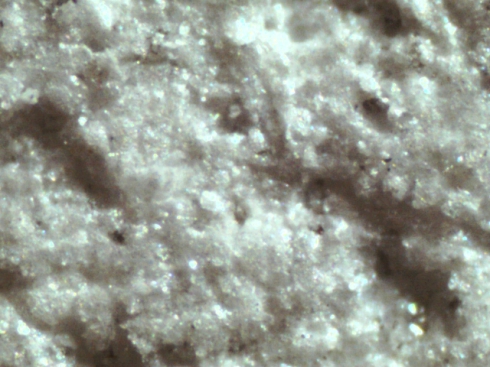

A typical NTST h-BN coating is illustrated below in Figure 1. Coating thicknesses of greater than 25 mils have been fabricated for this material. Materials characterization for NTST h-BN coatings includes a Vickers hardness of 44 (1.5 Mohs), surface roughness ranging from 235-375 microinches, bond strength greater than 3500 psia, and porosity less than 2%. Figure 2 illustrates the typical surface morphology of a h-BN coating.

Figure 1. h-BN coatings

Figure 2. As-sprayed surface morphology of h-BN coating