Latest NTST News:

New Hi-Tech Coatings:

Aluminum Nitride (AlN)

Boron Carbide (B4C)

Cubic Boron Nitride (c-BN)

Hex Boron Nitride (h-BN)

Chromium Nitride (CrN)

Fire Prevention

Porcelain

Silicon Carbide (SiC)

Silicon Nitride (Si3N4)

Tantalum Nitride (TaN)

Thermal Protection Systems Titanium Diboride (TiB2)

Titanium Nitride (TiN)

Zirconium Nitride (ZrN)

Download product bulletins at the "DOWNLOADABLE BROCHURES" section to the right >>>>>>

Download the "New NTST Coatings" Brochure for a short description of our newest products.

Need more technical information?

Click on the PRODUCTS tab above

Contact Information

call:

702-449-2154 Dominic

702-978-0151 Ron Kostick

email:

dominic@nevadathermalspray.com

or click for:

Nevada Thermal Spray Tech.

4842 Judson Avenue, Suite 115

Las Vegas, NV 89115

Thermal spray coatings are

used in over 50 industries

Silicon Nitride Coatings (Si3N4)

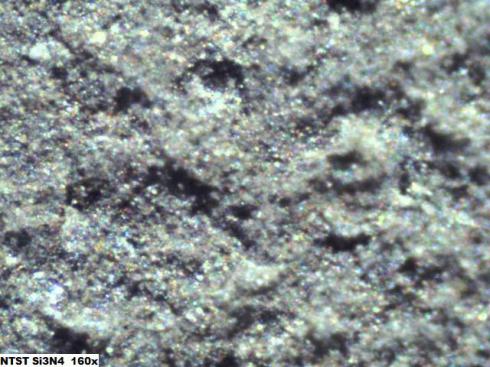

NTST has recently developed the unique capability to fabricate silicon nitride (Si3N4) coatings. Si3N4 is extremely difficult to fabricate as a coating due to its tendency to sublime at high temperature. It is a high-melting point solid that is relatively chemically inert and very hard (8.5 on the Mohs scale). The figure below illustrates typical NTST silicon nitride coatings (i.e. 5 and 10 mils thick).

slicon nitride has better high temperature capabilities than most metals. Benefits include low density, high temperature strength, superior thermal shock resistance, excellent wear resistance, high hardness and toughness, resistance to mechanical fatigue and creep, and good oxidation resistance.

Current applications are found in the automotive, industrial bearing, aerospace, medical, and electronics industries. The largest market for silicon nitride automotive components is in engines and wear components. This includes glow plugs, combustion chambers, turbochargers, and exhaust gas control valves. The wear resistance, low friction, and high stiffness of silicon nitride improves the performance of high temperature bearings.

NTST Si3N4 coatings are dense, hard, and wear resistant. Porosity is less than 2%, hardness is 8.3 (i.e. Mohs), bond strength exceeds 5000 psia, and surface roughness is 312 Ra (1696 Rz) microinches. Figure 2 illustrates the as-sprayed surface morphology of a typical NTST Si3N4 coating (160x).